The world is witnessing the emergence of new energy technologies just when they are needed most. These technologies are unlocking resources that once were too remote or challenging to develop economically and safely – and doing it more efficiently and sustainably.

Energy’s dynamic duo

One such breakthrough is geosteering: geology’s relatively unsung hero that, combined with a suite of technologies including horizontal drilling, brought about this new energy age. At Saudi Aramco, it is also bringing benefits to the development of supergiant oil fields. Most people think of horizontal drilling in tandem with hydraulic fracturing, but energy’s real dynamic duo is horizontal drilling for both conventional and unconventional reserves, and geosteering.

Combined, they led to our company’s technological and operational advantage through real-time reservoir modeling. By themselves, horizontal drilling and geosteering yield a picture of where you’ve been with the drill bit. But to make smarter decisions, you need to see what’s ahead.

That’s where real-time reservoir modeling pays dividends in drilling efficiency and timeliness for the subsequent interpretation process. It all starts, and ends, with geosteering.

The age of horizontals

Saudi Aramco is at the forefront of the age of horizontals, the drilling/geosteering revolution that began decades ago. Advancements reached the point where drilling technology enabled bit placement at ever more complex locations and geometries, and geosteering providers acquired and delivered the necessary formation data for geologists to interpret with increasing precision. This convergence led to the founding of our Geosteering Operations Center (GOC) in Dhahran.

While vertical wells are primarily used in exploration, production-oriented horizontal wells access a specific target. Unlike vertical drilling’s straight path, horizontal drilling can be steered at angles to create multiple wells (or laterals) from the single “mother-bore” for greater yield and a lighter environmental footprint.

Laterals increase the exposure of the oil/gas-bearing reservoir to the wellbore through which the fluids are produced. They navigate through subsurface rock thousands of feet below ground to areas that otherwise would be difficult or impossible to tap, positioning a horizontal lateral a few thousand feet into the reservoir.

While vertical wells might require drilling and pipe laid through hundreds of feet of rock in the reservoir, horizontal drilling’s tentacles may snake up to five miles in length, dramatically cutting production costs.

Horizontal wells save on another “currency,” too: the reservoir pressure that must be “spent” judiciously to allow for accurate recovery calculations, equipment placement and routine monitoring.

But in this era of proven world reserves outpacing consumption by billions of barrels, the new plenty is primarily unconventional oil and gas found in challenging rock, deep-water or Arctic “frontiers” whose mysteries only technology can unlock.

In short, drillers need a roadmap to the productive zone, or “sweet spot.” Real-time reservoir modeling built upon geosteering is what guides the horizontal well.

The fit-for-purpose advantage

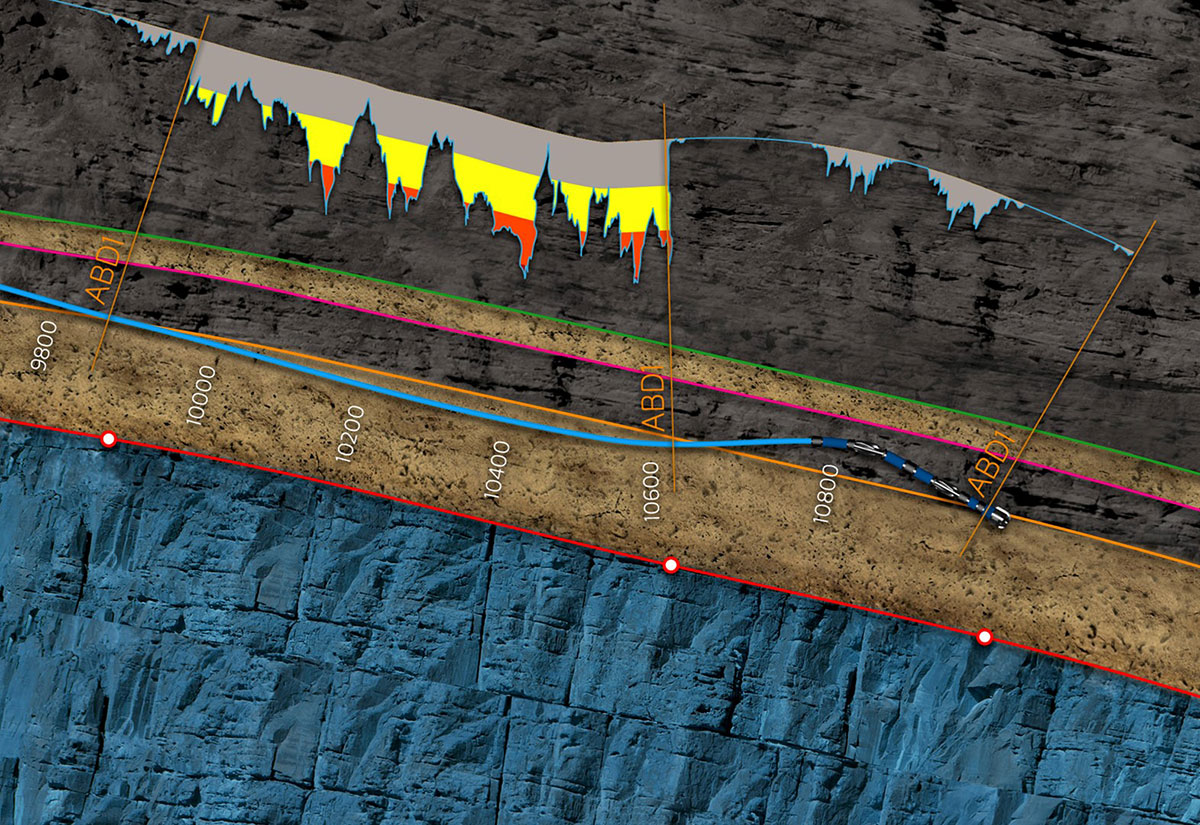

Geosteering has evolved from relatively low-resolution data to robust, real-time information that gives a better image of the reservoir and subsurface in the form of a digital geologic model – thanks to tools that go behind the drill bit.

The geologic model created from that data helps the drilling team circumvent challenges and steer horizontal wells toward pay-zone targets with near-perfect precision.

This highly complex, sophisticated process invites metaphors like driving a foggy mountain road with the car’s lights pointing backward – or a dentist who, from the rooftop, must drill the tooth of a patient in the basement.

Geoscientists glean real-time information through “Measurement while drilling” (MWD) which steers the drill, and “Logging while drilling” (LWD), which generates logs representing various rock-formation properties at depth. Most companies send geologists to the well-site to interpret this down-hole data, or use oil-field service companies that gather such data.

As one of the few energy companies with a centralised, round-the-clock geosteering operations center, Saudi Aramco is different. For development wells, our geoscientists don’t need to go to the rig. They direct the drill-bit in the subsurface from a centralised location, even hundreds of miles from the drill site. For every well, LWD sensors near the drill-bit send information about the reservoir and well trajectory up the hole to the drilling rig. From there, the data is transmitted via satellite to the GOC, which makes real-time activity possible.

Thanks to the precision of the model – a result of interpretation workflows that in turn are the result of fit-for-purpose technologies – we are almost always on the mark.

Saudi Aramco’s 2DCM (2D Conformal Modeling) allows us to create very accurate, “living” models of the reservoir shapes for all the data in fields (wells and seismic); these surface shapes are correct relative to the horizontal and high-angle wells. Without this intellectual property, existing technology generates surface shapes that are either non-conformal or do not honor the well data.

We build it once, then update continuously. This customisation takes geosteering from reactive to proactive, enhancing production by maximising reservoir contact and ultimate oil recovery with its real-time reservoir modeling.

Proprietary software runs quality control checks, then loads this data into the database and interpretation projects. The imaging tools deliver high-resolution geological, petrophysical and engineering information that can inform detailed geological analysis.

That knowledge determines the drill-bit’s location in relation to the pre-drilling plan and the reservoir target, and controls angle and direction. At a certain depth, the wellbore can be turned horizontally and steered to the optimum untapped areas of the reservoir. It’s a matter of connecting the dots: the more dots, the better the picture.

But completing that visualisation puzzle is no easy feat. Saudi Aramco needs to utilise every data point along the path of a horizontal well, just as the entire industry does with a vertical well; it comes with the territory of managing the assets of multi-reservoir, supergiant oil and gas fields.

This stewardship drives us to continue our fit-for-purpose path in developing proprietary workflows that could not otherwise be fulfilled by available commercial applications. Along with our knowledge of Saudi Arabia’s subsurface, what our professionals do with the data distinguishes us industrywide.

In other words, talent completes the technology. At Saudi Aramco, the vast majority of today’s development wells are high-angle/horizontal wells. The more data points available – especially the additional spatial coverage provided by horizontal wells – the greater the ability to make predictions.

Ambiguity is one of the biggest obstacles to gauging a well’s success rate. Structural uncertainty, such as depth or faults or fractures, can pose challenges. Geologic faults and reservoir variability can be unclear; field maturity can also create issues. Saudi Arabia’s rich reservoirs, with widely varying properties, are especially demanding.

On its own merits, a model is only as good as the amount and quality of the data available, and the geological insights that interpret that data.

Geoscientists have to ensure that the model honors the data from the drilling well and the conceptual geologic model of the field. Modeling know-how is where the GOC team stands out, updating both at and ahead of the bit through geological insights and fit-for-purpose technology. In their hands, the predictive tool aids intuitive, interactive decisions, mitigating uncertainty that can translate to expensive delays, higher development costs, and poor results.

The sweet spot

Optimal bit placement results in maximum reservoir contact (MRC) so as to maximise recovery of targeted oil and gas. The technology positions the well spatially, based on objectives.

Information is used to define and refine the shape of the field within the model (the rock inside the space and its reservoir properties) and to predict ahead of the bit. This 3-D model of reservoir characteristics shows the entire field in continuity.

From this roadmap, geoscientists go for the strict target parameters. The Oreo™ cookie analogy for this physically and mentally tough process is famous among geoscientists: they must focus exclusively on the cream center (sweet spot), without touching the wafers (non-reservoir rock).

Every well fulfills a specific objective, whether production, injection or otherwise. It’s necessary not only to position each well spatially and accurately in the subsurface reservoir, but with exacting precision. With a horizontal well, that happens along its multi-thousand-foot extent within a very narrow margin of tolerance – approximately one foot in any direction. Our geosteering technology makes such maneuvering possible.

Competitive advantages

With each professional at the GOC monitoring up to five drilling wells in different fields and different reservoirs at a time, data is coming into the GOC from as many as 100 wells at any given moment. Accordingly, the GOC works around the clock.

In 2018 alone, the GOC oversaw 900 high-angle/horizontal laterals and geosteered almost 1800 kilometres including more than 600 kilometres within the reservoir section itself.

Saudi Aramco started drilling horizontal wells in 1990. By the colossal developments of Shaybah field at the end of that decade, there was no looking back: horizontal drilling’s efficiency and economics made it Saudi Aramco’s primary choice in continuing to develop oil and gas fields.

The gradual growth in this trend paralleled the developing geosteering function. In 2000, Saudi Aramco geosteered about 100 wells. By 2008, the number of geosteered wells had reached almost 800 – a bump of 700%. Today, with the number standing at more than 1,000, geosteering continues to clearly align with the company’s goal of realising the full value of its assets in the most sustainable way.

That stewardship is important. With the global quest for energy security, higher production is vital for keeping economies on track – and affording emerging nations the better living standards that modern energy alone can provide.

Geosteering’s lighter footprint boosts the sustainability factor of natural gas as a lower emitter of CO2. That fact directly relates to society’s expectation that the industry take ownership of further reducing crude oil’s greenhouse gas intensity and minimise the environmental impact of our operations.

Also, drilling the horizontal well in optimised fashion supports future innovation and well-completion plans, to serve future generations at home and abroad.

Safety is another advantage. Without geosteering, each rig would require two or three geologists to place each well properly in its target zones. With a hundred rigs or more, many people would be driving back and forth. Geosteering has been a game changer in this regard, as placement of each well remotely and in real time is far safer and more cost-effective.

The future of geosteering

We are moving beyond the zone of interest to full-field reservoir models. With many fields containing multiple productive horizons, the full-field model will help keep the complete inventory of reserves-to-be-produced ready for tomorrow – increasing confidence in our reserves and making them production-ready.

Saudi Aramco is moving toward 100% precision through logging, leveraging in technology and new advancement in its applications.

Looking back, we took what we did for granted, as just a workflow. But this reinvention of how we shape the reservoir relative to horizontal wells is bigger than that. By using every piece of data in the model, we’ve achieved something few others are doing: a horizontal well solution using all data points precisely, effectively and efficiently – and updated in real time for consistent results in lightning-bolt speed.

To level the playing field, we have worked with service providers to bring their tools to minimum requirements. Our next challenge is to bring the global industry on board. Simply put, the technology cannot be developed or applied without the full community of enablers and users.

With growing energy demand on the horizon, next-generation technologies and techniques will be needed. A good-enough industry practice will no longer be good enough. Saudi Aramco’s proven, paradigm-shifting geosteering innovation is here to rise to the occasion.